Film Length = 18,000 Meter

Film Width = 890 mm

Ink gsm = 1.5

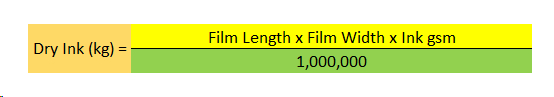

How to Calculate Dry Ink for above Film ?

dry ink (kg) = Film Length x Film Width x Ink gsm / 1,000,000

Film Length = 18,000 Meter

Film Width = 890 mm

Ink gsm = 1.5

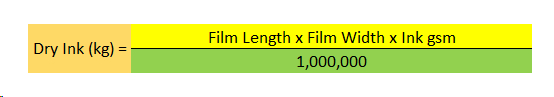

How to Calculate Dry Ink for above Film ?

dry ink (kg) = Film Length x Film Width x Ink gsm / 1,000,000

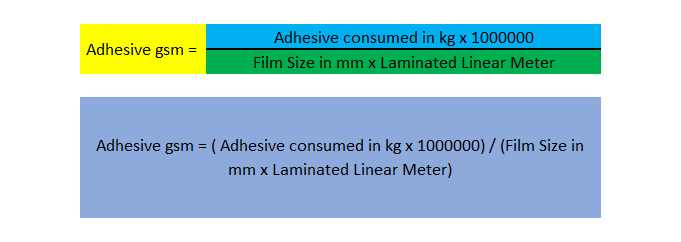

Adhesive consumed – 100 kg

Laminated Meter – 50,000

Coil/Film Size – 1200 mm

Adhesive gsm = (Adhesive Consumed x 1000000) / (Coil x Meter)

Adhesive gsm = (100 x 1000000) / (1200 x 50000) = 1.66 gsm

SKU (pronounced “skew”), short for Stock Keeping Unit.

Retort Pouch, is a flexible pouch for low-acid foods that are thermally processed in a pressure vessel, often called a “retort.”

The pouch is made of layered polyester, aluminum foil, and polypropylene. Commercial sterilization occurs at temperatures greater than 212 °F (100 °C), typically 240 to 250 °F (115. to 121 °C). The retort packaging is shelf stable at room temperature.

Structure of Retort Pouch

In Flexible Packaging we come across various type of Pouches every name.

We may come across Pouch based on Application as well

Tie Layers help adhere polar (EVOH, PA etc.) resins to non-polar (PE etc.) resins in single-step co-extrusion process.

Ethylene-vinyl alcohol co-polymer or EVOH is a flexible, crystal clear, and glossy thermoplastic co-polymer with excellent flex-crack resistance, and very high resistance to hydrocarbons, oils and organic solvents.

It also has some of the best barrier properties to gases such as oxygen, nitrogen, and carbon dioxide making it especially suited for packaging of food, drugs, cosmetics, and other perishable or delicate products to extend shelf life.

When compared to other common films, EVOH is considered to have superior barrier properties.

However, when exposed to moisture, EVOH loses its good gas barrier properties. For this reason, EVOH is often used in a multi-layer co-extruded film structure with materials such as HDPE, PP and PET, all of which have superior moisture barrier properties.

A polymer is considered polar if the it’s charge can be measured as positive or negative.

If a polymer has no charge, we say it is non-polar.

Some examples of polar plastics are PA, PC, PMMA, and ABS.

The most common non-polar plastics are PP, PE, SEBS, PS and PTFE.

When two or more Polymers are molted simultaneously to form a single sheet of film, that film is known as “Co-Extruded Multi-Layer Film” and process is known as Co-Extrusion.

In Flexible Packaging, no single Layer of Film can give all required properties. In order to achieve all selected Polymers were melted in such a way that form a film with Unique Properties of all Films.

Co-extrusion is the process where two or more polymers are extruded together to make a composite film.

Type of Co-Extruded Plants

The selection of layers depends upon end properties required as well as items to be packed.

Trim Waste in kg = weight of roll x trim size in mm / roll size

Weight of Roll = 325 kg

Rolls Size = 875 mm

Trim Size = 15 mm

Trim Waste in kg = 325 x 15 / 875 = 5.57 kg

Trim Waste % = trim size / roll size %

Trim Waste % = 15 / 875% = 1.71%