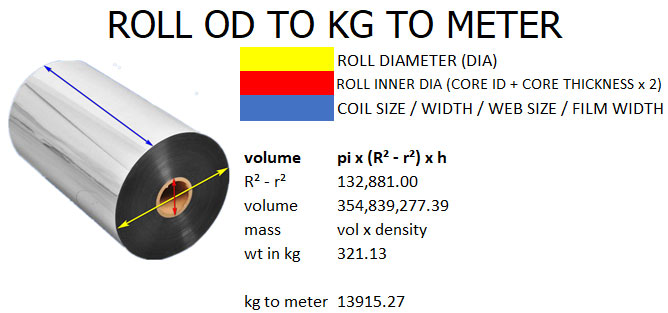

Convert Roll OD to kg

Formula = pi x h x (R² – r²) x film density / 1000000

pi = 3.14

h = film / web / roll width

R² = square of Roll OD Radius (R = OD/2)

r² = square of Roll ID Radius (r = ID/2)

film density = BoPP 0.91, Pet 1.4, Foil 2.7

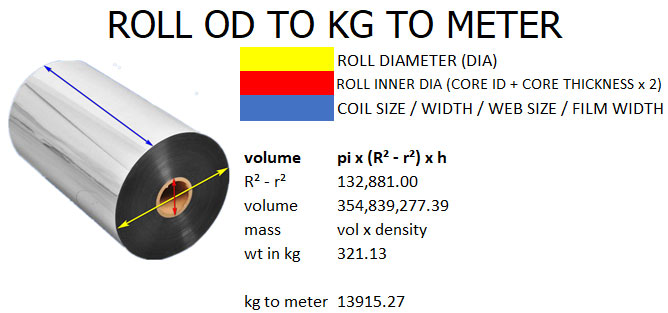

Convert Roll OD to kg

Formula = pi x h x (R² – r²) x film density / 1000000

pi = 3.14

h = film / web / roll width

R² = square of Roll OD Radius (R = OD/2)

r² = square of Roll ID Radius (r = ID/2)

film density = BoPP 0.91, Pet 1.4, Foil 2.7

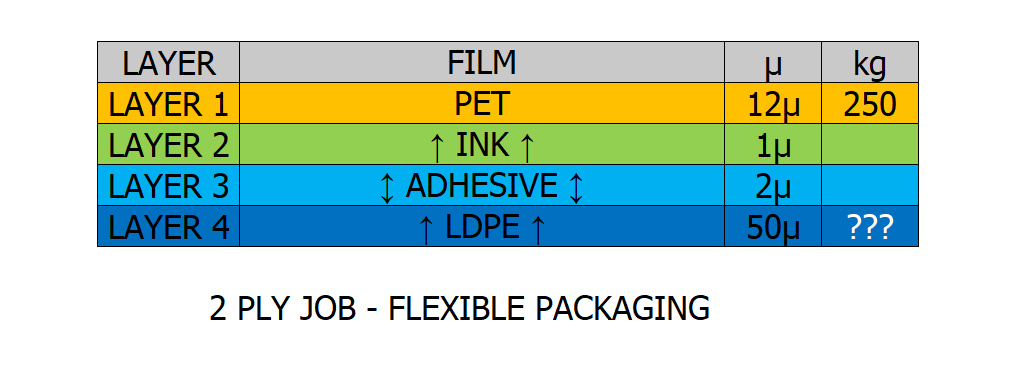

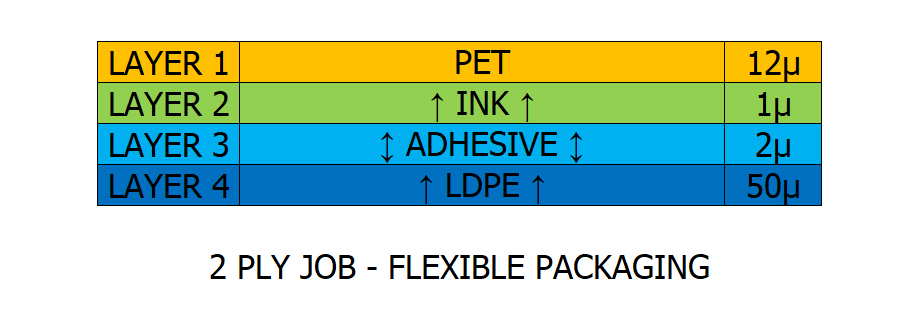

1st Layer – 12µ Pet Density 1.4

2nd Layer – 50µ LDPE/Poly (Natural) Density 0.93

How much 2nd Layer required for 250 kg Pet ?

2nd Layer gsm x printed Quantity ÷ 1st Layer gsm

(50 * 0.93 * 250) ÷ (12 * 1.4) = 691.96 kg

1st Layer Pet 12µ – 250 kg

2nd Layer Poly 50µ – 691.96

Final Laminated Material required 1000 kg

Job Structure 12µ Pet + 50µ LDPE

Pet Density 1.4

Poly Density 0.93

12µ Pet gsm = 12 x 1.4 = 16.8

50µ Poly gsm = 50 x 0.93 = 46.5

Composite gsm = Pet Film gsm + Poly gsm = 16.8 + 46.5 = 63.3

Pet required for 1000 kg Laminate = Pet Film gsm x Total Output ÷ Composite gsm

= 16.8 * 1000 ÷ 63.3 = 265.40 (kg)

LDPE required for 1000 kg Laminate = LD Film gsm x Total Output ÷ Composite gsm

= 46.5 * 1000 ÷ 63.3 = 734.60

Total Laminate (Pet + LDPE) = 265.40 + 734.60

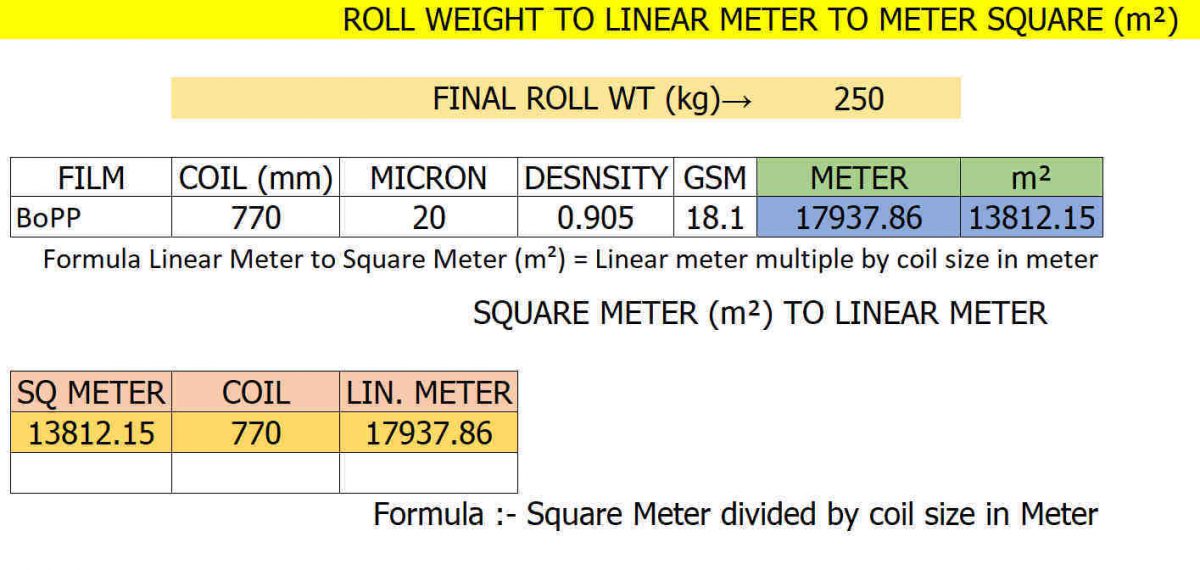

Convert Roll kg to Meter to Meter Square Flexible Packaging using Excel Sheet.

In any Flexible Packaging job, we have to convert Running Meter or Linear Meter to Square Meter (m²). In this video you can learn and use Excel Sheet to Convert Linear Meter of Film (BoPP, Pet, LDPE etc.) to Square Meter. First we convert roll kg to meter using subjected Roll Width or Coil Size.

Liquid Ink = 4 times of dry ink. Assuming 25% solid content in liquid ink.

Printing Layer – Pet

Film Density – 1.4

Film Micron – 12

Film gsm – 16.8

Job Sample Ink gsm – 1.2

Printing Layer Quantity – 300 kg

Dry ink required = (ink gsm x printing Quantity)/printing Layer gsm

= (1.2 x 300) / 16.8

= 21.42 (dry ink)

Liquid Ink = 4 times x dry ink (solid content of liquid Ink 25%)

= 4 x 21.42 = 85.68 kg (Liquid ink)

Mylar is actually the name of a popular polyethylene terephthalate (PET) film from DuPont Teijin FilmsTM.

Mylar is technically BoPET (biaxially-oriented polyethylene terephthalate).

It has been a prominent film in a variety of applications across

– electronics

– food packaging

– industrial specialty

– cast & release

– graphics markets

Due to its balanced tensile properties, good adhesion, excellent moisture and chemical resistance, and ability to withstand temperatures from -100°F to 300ºF.

Mylar® polyester films are ideal products for high volume, dependable industrial performance, where lower cost initiatives must be met.

Roll OD or Roll Outer Diameter is a measurement of the distance of a straight line from one point on the outer wall of the Jumbo Roll, through its center, to an opposite point also on the outside.

Generally it’s measured in mm (millimeter).

for eg. Maximum Jumbo Roll OD should be 650 mm for Printing/Lamination Machine.

Biaxially oriented, means that the film is stretched in two different directions to increase strength and modulus (lower elongation and higher stiffness).

Density 1.4

Polyester film is a high-performance, crystal clear thermoplastic made from Polyethylene Terephthalate (PET) resin.

In comparison with other common plastic films, PET film has high tensile strength, excellent dimensional stability, low moisture absorption, and good retention of physical properties over a fairly wide temperature range.

It also has superior UV resistance and excellent electrical properties, and good optical clarity. Because of its higher price relative to PVC, PE, and PP film, it is generally considered a specialty film.

PET Film – 150°C (302°F) and as cold as -70°C (-94°F)

Properties

Application

Density – 1.15

Polyamide (PA), also known as Nylon, is a clear and printable thermoplastic that has a relatively high melting point, exceptional strength and toughness, and good oxygen barrier properties.

It is also scratch, puncture, and flex-crack resistant and does not dissolve or absorb grease, oil, and acidic food.

These properties make PA ideal for use in conventional and microwave cooking applications.

The two most common types are cast and biaxial oriented Nylon film. Biaxial oriented polyamide or BOPA film can be used for a wide variety of applications especially where high gas barrier properties are required. Because of its higher price relative to PVC, PE, and PP film, it is generally considered a specialty film.

Application