Ethylene-vinyl alcohol co-polymer or EVOH is a flexible, crystal clear, and glossy thermoplastic co-polymer with excellent flex-crack resistance, and very high resistance to hydrocarbons, oils and organic solvents.

It also has some of the best barrier properties to gases such as oxygen, nitrogen, and carbon dioxide making it especially suited for packaging of food, drugs, cosmetics, and other perishable or delicate products to extend shelf life.

When compared to other common films, EVOH is considered to have superior barrier properties.

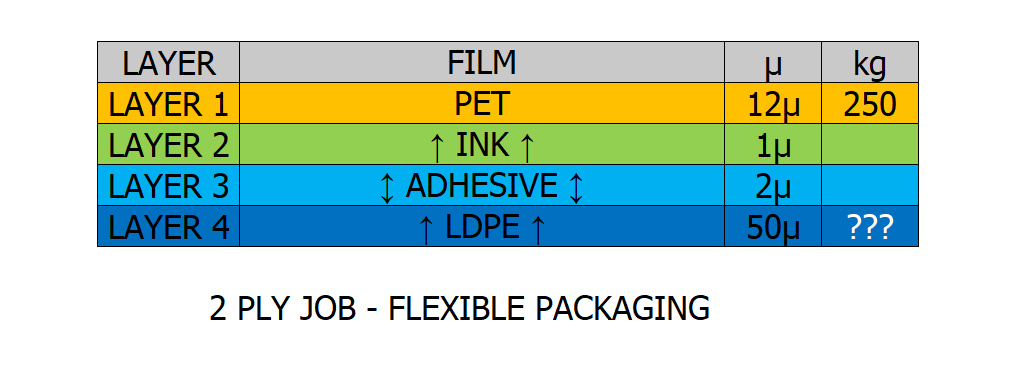

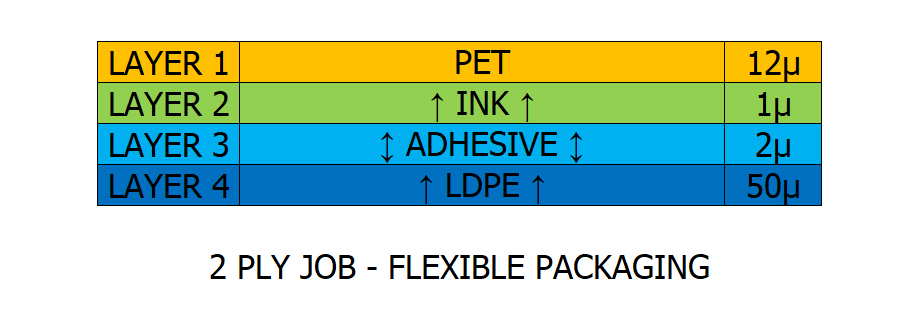

However, when exposed to moisture, EVOH loses its good gas barrier properties. For this reason, EVOH is often used in a multi-layer co-extruded film structure with materials such as HDPE, PP and PET, all of which have superior moisture barrier properties.