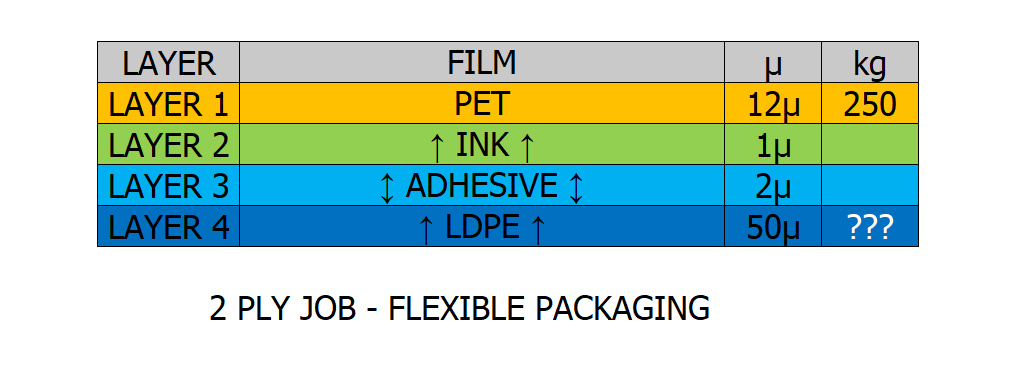

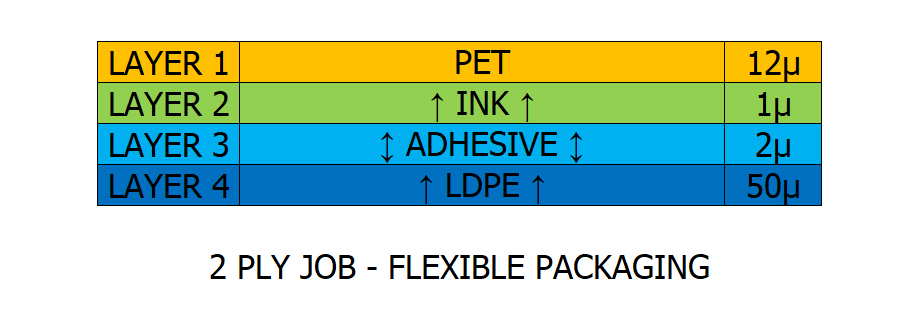

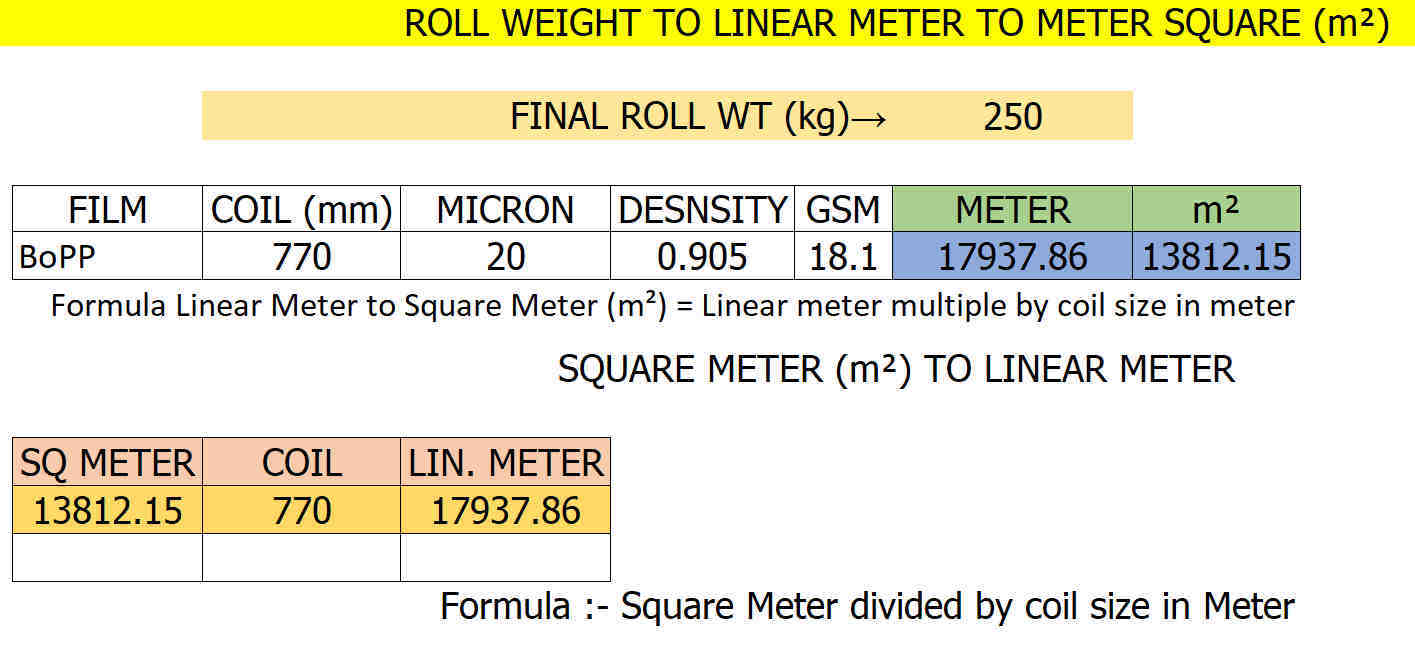

1st Layer – 12µ Pet Density 1.4

2nd Layer – 50µ LDPE/Poly (Natural) Density 0.93

How much 2nd Layer required for 250 kg Pet ?

2nd Layer gsm x printed Quantity ÷ 1st Layer gsm

(50 * 0.93 * 250) ÷ (12 * 1.4) = 691.96 kg

1st Layer Pet 12µ – 250 kg

2nd Layer Poly 50µ – 691.96